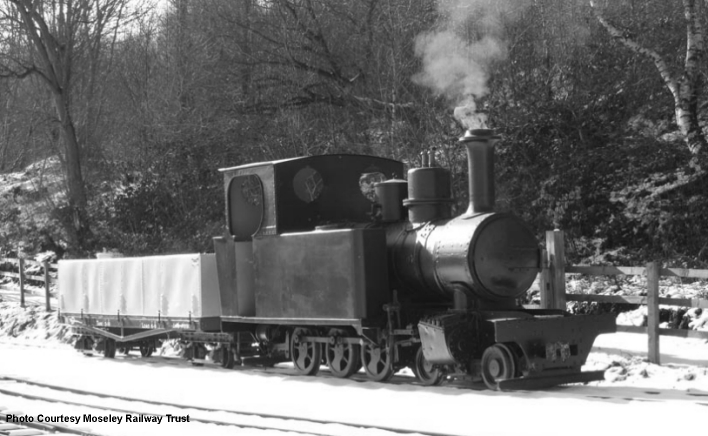

What is significant about these locos?

Apart from being one of the largest class of one single type of narrow gauge loco built within the UK the vast majority were also completed within the space of three years. There were 155 ordered by the War Department from Hunslet for use behind the trenches during WW1 for the movement of personnel, munitions, and equipment. They were completed at a time when Hunslet were also constructing howitzers, shells, and machinery to make shells as well as a limited number of other locos. By comparison, in peace time they averaged about 40 locos of all designs per year.

The other remarkable feature of these machines is the diverse locations that they and the 9 built post war, ended up in. Scottish Highlands, to the Pampas of Argentina, Harrogate gasworks to Australian Canefields, Oxfordshire Ironstone to Palestinian Power Stations.

In 2005, the War Office Locomotive Society repatriated Hunslet 1215, and is now working to get 1215 back into steam. Oakwood Press publish our book if you want to know more on the history of Hunslet 1215.

Our original target was 2014 for the anniversary of the start of WW1, and to this end we finalised a plan to speed up restoration work, starting in early 2012. This got under way with the transfer of the loco to the restoration workshop and complete stripping for detailed assessment.The move and the ongoing workshop costs being supported by various means as detailed in the "How you can help" tab above.The loco was also formally transferred to the Trust which is a registered charity, and is able to claim gift-aid, so if you do donate please send us a completed form. Many thanks!

2013 started well with the news that the Arts Council had awarded us a PRISM grant for the first phase of the project and work could get underway on the chassis, subsequently in the autumn a major boost was a donation from a well known heritage railway supporter of£5000 followed by the generous offer that if we raised a further £5000 he would match it, but it had to be done by the end of November, While we focussed on spreading the news and fund raising to take up the offer, further news came at the end of September. A nice man from the Heritage Lottery Fund rang up wanting to check some details on our application for funding for the boiler and by the way we have awarded you the full amount requested..... To say this was the best news all year was an understatment as we could now get on with the boiler too. Shortly afterwards the Transport Trust contacted us to say that we had been awarded £1500 from the Alan Moore Award which is a great piece of recognition for the work put in by the volunteers at the workshop, then last but not least a fantastic effort by our donors and supporters meant that first week of December I could contact our benefactor and say "We've done it, and raised our matching £5000".

This set us up well for 2014, with the boiler design completed, tendered and ordered, but some big costs hit the chassis funds for example the need to replace the bogie tyres and the driving axle springs. The team was also trying to complete Hudswell Clarke 1238 (another WW1 era loco) so the decision was made to use a contractor to do a final straighten of the frames, polish up the hornguides, and machine up the new axleboxes to match.

The Hudswell job did take longer than expected but the results are fantastic and can now be seen at the Apedale Valley Railway, so come September 1215 returned to the caring hands of the volunteer team and now has their entire attention.

All this is great the restoration had come on leaps and bounds since its return (see the restoration files) and are confident we are passed the worst, but your support is still needed. As with any restoration project there are surprises and hiccups,and now we have to cover the entire cost of running the workshop and working through the remaining tasks.

In early December our benefactor offered a further £10000 if we could match it by the end of March 2015 in an effort to get us onto the home straight. Well I am glad to say that thanks to the generosity of our donors old and new in addition to a grant from the Foyle Foundation we achieved that target. Along with the wins always come a few disappointments and the news that all 4 link stays for the boiler required forged replacements for almost £5000 was a set back. However, the news of another grant, this time from the Garfield Weston Foundation matched that figure.

The end of 2015 has seen the crossheads and slippers assembled onto the slidebars, rear coupling rod sections rebearinged and fitted, axles, axleboxes and all suspension gear has been delivered and after a slight hiccup with the springs is now finished. All the brake gear is now complete with the last component being a replacement link from the steam cylinder to the weighshaft.Bunker and tanks and cab are on with much pipe work being threaded up and down the frames for lubrication and train brake systems. The boiler finally landed in early February and ever since work has carried on to create and fit crinolines cladding, ashpan and attach all the fittings. Back in September we assembled a detailed list of what we thought would be needed to finish the job, this was the basis of what hoped to be the final appeal for £20,000, and incredibly our main benefactor again offered to matchfund it, and by Christmas we were at £8,500 once Gift Aid was claimed,and consequently managed to match into the new year. The work does go on and 1215 has continued to throw up some last challenges so please continue to support us and help finish the job, just go to the "How you can help" tab above. We do continue to try and find further sources of grants and managed to obtain £1000 from the Veronica Awdry Trust and yes it is that Awdry family!

2016 has continued being a busy year since the boiler arrived strides forward with one or two setbacks on the way (eg the LH cylinder being found to be slightly smaller diameter in the middle than the ends), however despite valiant efforts 1215 was not going to be ready for its own centenary.The rest of the year has seen finishing work on the cylinders, now fully bolted up, the assembly and setting of both sets of valve gear, the near completion of air and vaccum train brakes, manufacture of almost all the boiler cladding (including some very complex firebox shoulders), the arrival of the last backhead fittings (only injectors to do now), the creations and completion of an ashpan and of course an awful lot of painting and sanding.A trial fit of the boiler points at the need to modify the frame stretchers, but other than that we are heading rapidly towards the final completion.

Onwards into 2017, as noted above the boiler had to come back out to allow stretcher removal for modification. It also allowed work on the cab roof to make it a better fit and to finish off the front panel. Coupling rods have been fitted, though not without some trials and tribulations on the left hand side, likewise the connecting rods have been finished and fitted, but again with issues requiring some more machining work on the left hand side. The final section of cladding over the lead shoulders of the firebox are now approaching completion, there difficulty is not to be underestimated given that they seem to curve in all directions. Other items that curve in all directions are the steam pipes that link the live steam feed T piece that is fed from the regulator, with the vertical sections that are screwed into the live steam port of each cylinder. A recent delivery has been the draincocks, a combination of new and rebuilt ones which leaves the below footplate work almost all done, apart from the injectors which are away for overhaul. Given that we are retaining the Australian underfloor ones it has been felt neccessary to install silt traps under the tanks. These have not been cheap but are being made to an original Hunslet design that was used on the later versions of the loco that had water lifters. The boiler has now been returned to the frames to allow further work on the fit of the smokebox to the saddle. With that done we should be heading for a steam test fairly soon. However we do need continued support during this final phase, as the loco has continued to throw up challenges!

So we reach 2018 and at the turn of the year we know she will be steaming come spring, as by Christmas 2017 the remaining few brass items had landed, and almost all pipework was complete, so the stripdown for testing was started. The cab and tanks were soon off, so the opportunity was taken to finish off some other jobs like the cladding and fettling the revised frame stretchers ready to go in. The boiler washout plugs just would not fit between the original design ones. Soon will come the updated hydraulic test, swiftly to be followed by the steam test, and assuming that is successful then comes reassembly and off for operational commissioning - exciting times!

That was the plan, but as always 1215 had other ideas. The loco was moved to the larger main workshop and stripped for a fresh hydraulic test. This now raised a couple of issues, that were successfully resolved, but did knock back the plan by 8 weeks by the time everything was ready and we could line up a very busy boiler inspector to witness the successful hydraulic test and fairly soon afterwards the successful steam test on April 19th 2018 - The 10 year ticket has now started!

Finally a thank you to all those who have come forward and donated or assisted in other ways large and small, we would never have made the progress we have or obtained the grant support we have without you. Donations and support are still very welcome as we are facing a longer stay in the workshop than planned, and we do need to obtain a container to use as a store once it heads to its home railway.

Ps - a bit of fun Photos and Videos has a cab ride in 1215. With YOUR help next time we won't need the diesel!